Seeing at once Hyundai Ev Ecosystem in 3 factories is no doubt attention-grabbing. On this case, the Motomobinews crew noticed firsthand the method of manufacturing of electrical cars from Hyundai.

Hyundai continues to verify its place as a pioneer of electrical automobiles in Indonesia via re -strengthening the dedication of the sustainability of EV manufacturing within the nation. This dedication used to be confirmed during the initiative of PT Hyundai Motor Production Indonesia (HMMI) which held the Hyundai EV Ecosystem Excursion 2025.

The job presentations the lifestyles of 3 Hyundai factories in Indonesia, specifically HMMI, HLI Inexperienced Energy (HLI), and Hyundai Power Indonesia (HEI) because the Rengkaratan Ecosystem of Entire and First Electrical Cars in Indonesia.

“Hyundai has been recognized for its EV traces that supply top class high quality, top era, and certified efficiency. That is inseparable from our dedication in making sure precision and cutting edge manufacturing actions. All of our technicians have additionally long gone thru strict competency assessments to be sure that each and every car reaches the fingers of customers with the most efficient high quality and safety requirements,” defined PT Hyundai Motor Production Indonesia, Bong Kyu Lee (14/5).

Hli inexperienced energy and hello ensure secure battery high quality

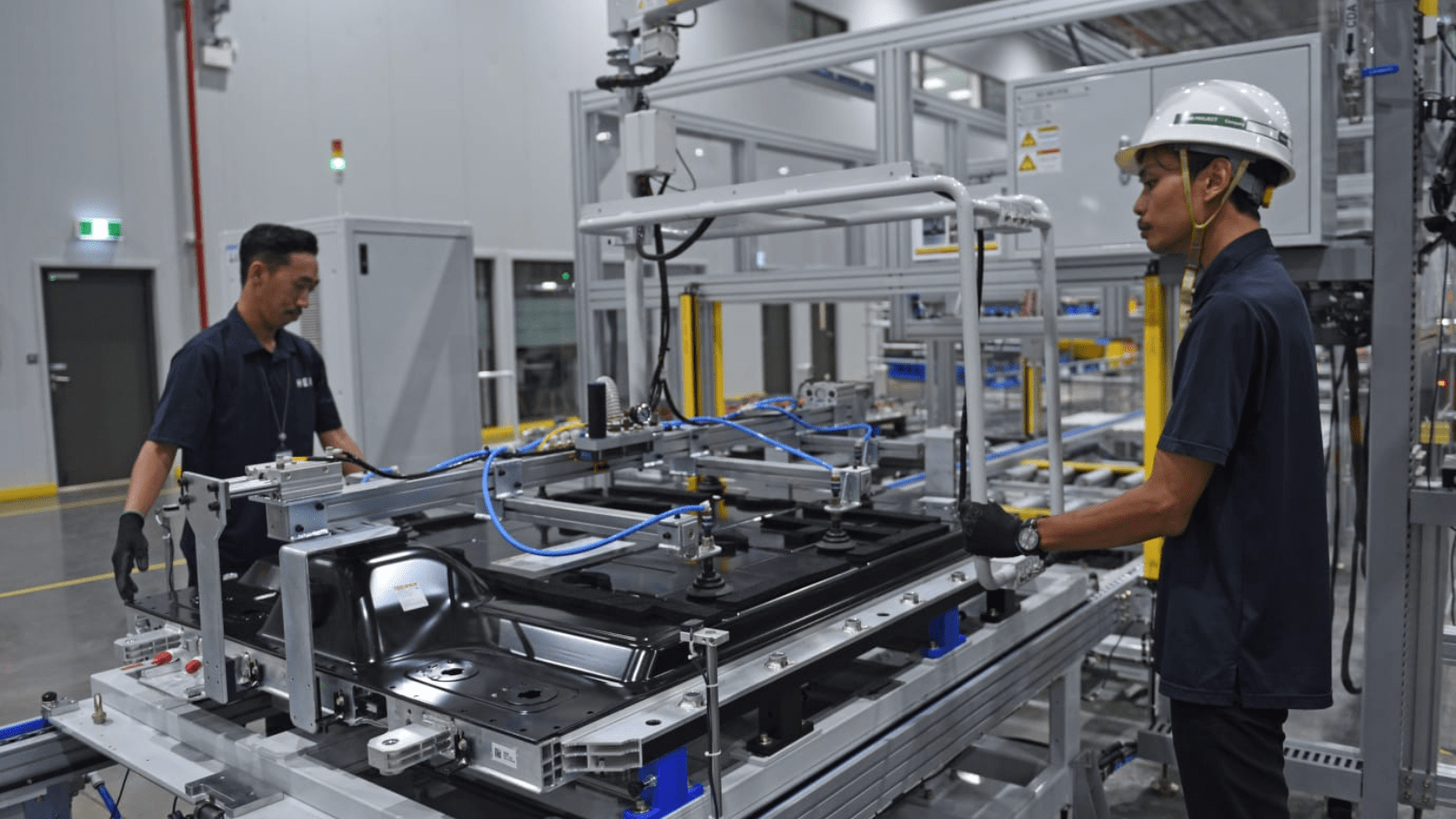

Hyundai EV Ecosystem is supported via 3 factories, specifically HMMI, HLI and Hi there. On this case PT HLI Inexperienced Energy and Hyundai Power Indonesia make stronger the battery aspect embedded in different Hyundai cars.

Battery mobile manufacturing in HLI Inexperienced Energy contains 3 major processes: Electrode Production, Mobile

Meeting, and formation. Electrode production is the degree during which the cathode and anode are combined, lined (coating), and compacted thru roll urgent to shape a flat electrode.

This electrode is then during the Slitting, Not anything, and Drying way to resemble the preliminary form of the battery mobile. Then, Mobile Meeting is the method of getting ready the electrode the use of the Complicated Zigzag Stacking way to regulate the form and construction of the battery.

Moreover, on the formation degree, the battery is stabilized during the technique of charging and tool unlock accompanied via gasoline elimination and high quality inspection.

The function of HMMI and HLI Inexperienced Energy to hold out the manufacturing technique of Hyundai electrical automobiles in the community and comprehensively may be supported via the presence of Hyundai Energi Indonesia (HEI).

In Hi there, the method of getting ready a battery module is composed of the preparation of battery cells, packaging, and the method of integration of battery cells thru welding.

After that, the battery mobile can be organized into an entire battery machine for then trying out utilization. The check contains battery intake, charging high quality, to the stableness of the ability present.

![VVS: Meet the Emerging K-Pop Woman Crew Set to Shine Like Diamonds [Teaser Images] – Kpoppie VVS: Meet the Emerging K-Pop Woman Crew Set to Shine Like Diamonds [Teaser Images] – Kpoppie](https://i1.wp.com/kpoppie.com/wp-content/uploads/2025/04/vvs-man-100.jpg?w=100&resize=100,100&ssl=1)

You must be logged in to post a comment Login